Foundry, machining and forging

More than 5 years of casting service and machinig components

Our company produces ductile iron and gray cast iron series products, with an annual output of 30,000 tons, products are exported to the United States, Germany, Italy, Russia, Brazil, Perú, and other regions. The casting parts from 1kgs to 10000 kgs.

OUR PRODUCTS300+

Finished Products

268 000+

Items for year

5+

Years working for the world

8 000+

Items for year

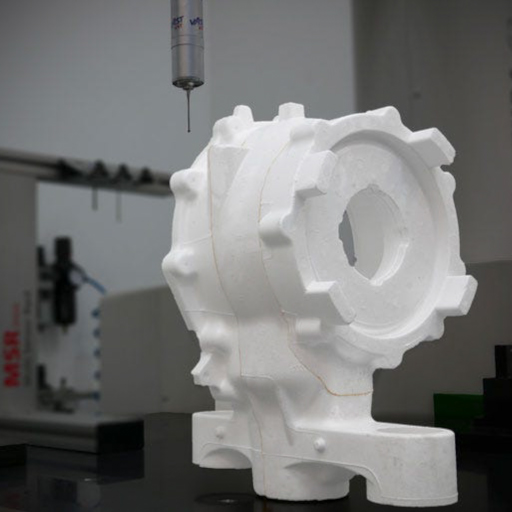

Shell mold casting is a precision casting process that uses a thin, hardened shell of sand and resin as the mold material.

Shell Mold Casting

This process is renowned for its ability to produce complex and detailed metal components with high accuracy and an excellent surface finish. Developed as an improvement over traditional sand casting, shell mold casting is commonly used for medium to high-volume production of small to medium-sized parts.

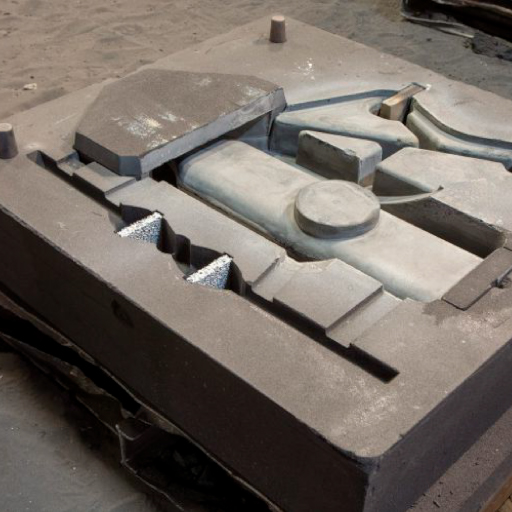

Green sand casting

It involves creating molds using “green sand,” a mixture of sand, clay, water, and sometimes organic additives. Despite the name, “green” refers to the damp condition of the sand rather than its color. This process is versatile, economical, and suitable for producing a wide variety of metal parts in different sizes and shapes.

Green sand casting is one of the most widely used and cost-effective metal casting processes.

Also known as self-hardening sand casting, is a metal casting process that uses chemically bonded sand to create molds.

No bake resin sand casting

Unlike traditional green sand casting, no-bake sand molds harden at room temperature without the need for heat or pressure.

Shell Mold Casting

This process is renowned for its ability to produce complex and detailed metal components with high accuracy and an excellent surface finish. Developed as an improvement over traditional sand casting, shell mold casting is commonly used for medium to high-volume production of small to medium-sized parts.

Shell mold casting is a precision casting process that uses a thin, hardened shell of sand and resin as the mold material.

Shell mold casting is a precision casting process that uses a thin, hardened shell of sand and resin as the mold material.

Shell Mold Casting

This process is renowned for its ability to produce complex and detailed metal components with high accuracy and an excellent surface finish. Developed as an improvement over traditional sand casting, shell mold casting is commonly used for medium to high-volume production of small to medium-sized parts.

Shell Mold Casting

This process is renowned for its ability to produce complex and detailed metal components with high accuracy and an excellent surface finish. Developed as an improvement over traditional sand casting, shell mold casting is commonly used for medium to high-volume production of small to medium-sized parts.

Shell mold casting is a precision casting process that uses a thin, hardened shell of sand and resin as the mold material.